Britta Pedersen-Pool/Getty Images

- SpaceX almost ran out of money in 2008, and had one last chance to launch a rocket to orbit.

- Its one remaining rocket began to implode while flying onboard a C-17 jet, according to a new book.

- So engineer Zach Dunn crawled inside the rocket to stop its collapse and save SpaceX.

- See more stories on Insider's business page.

SpaceX almost died aboard a C-17 jet above Hawaii.

In 2008, before the company had successfully launched a single rocket, two dozen SpaceX engineers were transporting its Falcon 1 rocket to Hawaii inside an Air Force jet. From there, a barge would carry it to the company's launch facilities in the Marshall Islands for one more launch attempt. It was the company's last chance: If this failed, SpaceX was done for.

But as the jet descended ahead of landing, the SpaceXers heard "a loud, terrible, popping noise," according to a new book by Eric Berger, a journalist and senior space editor for Ars Technica. The rocket was imploding due to a pressure imbalance. So Zach Dunn, one of SpaceX's greenest engineers, crawled into its belly. His quick fix saved the company – and possibly his own life.

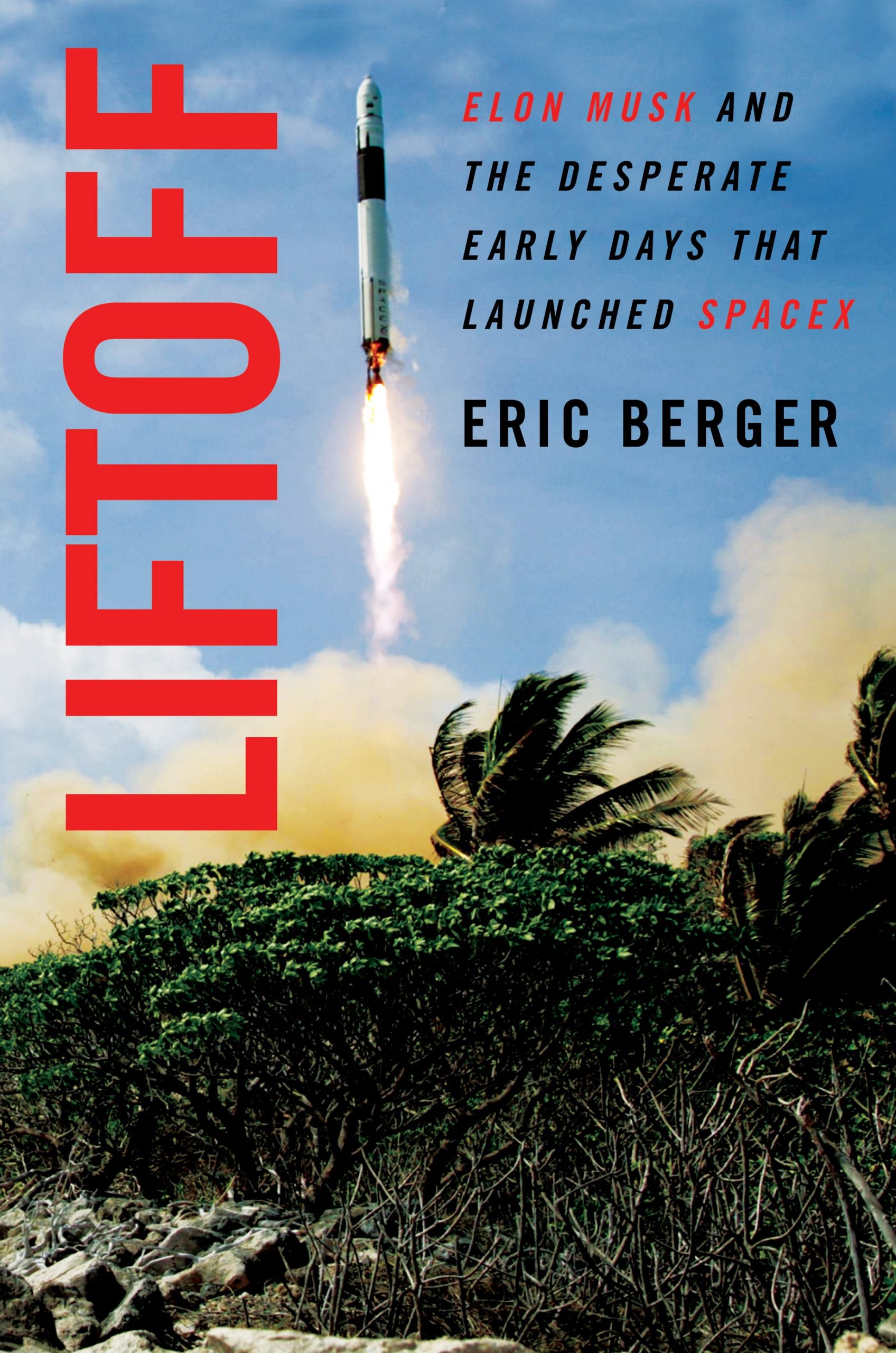

Berger's book, "Liftoff," documents this moment and other wild, breakneck events from SpaceX's early years – including the construction of a launchpad on a remote island, a mutiny staged by engineers trapped on that island without food, and the scramble to send a commercial rocket into orbit.

SpaceX finally reached orbit using the very rocket that nearly crumpled in mid-air.

SpaceX engineers faced a mid-flight emergency

By September 2008, SpaceX was almost out of money. The company had failed in all of its attempts to launch a rocket to orbit, so it wasn't winning any contracts. Musk was running out of cash to pump into SpaceX and Tesla, which were both floundering as the recession hit. SpaceX had enough resources for just one more launch attempt.

Musk gave his engineers six weeks for the Hail Mary effort. When they were ready to transport the Falcon 1 rocket from California to the Marshall Islands, the engineers piled into the C-17 jet at Los Angeles International Airport. For the first few hours of the flight to Hawaii, they cruised smoothly above the Pacific, kicking back in cargo-compartment seats surrounding the rocket. Someone broke out a guitar.

But on the descent, loud pops and pings rang through the cargo area as dents appeared along the rocket's body. The engineers realized that its liquid-oxygen fuel tank was not venting enough air to keep up with the changes in pressure as the jet descended.

The tank was basically "breathing through a straw," Berger writes.

As the pressure in the jet's cargo bay increased relative to the pressure inside the rocket's fuel tank, the Falcon 1 started to crumple.

"The first thought I had was that this thing is going to implode and rebound," Anne Chinnery, who was managing SpaceX launch operations at the time, told Berger. "And it would kill all of us who were sitting next to the rocket in the airplane jump seats. So I hopped up and told everybody to get to the front of the rocket."

Dunn, who'd joined SpaceX as an intern in 2006 then quickly ascended to become a propulsion engineer, was about to save the rocket, its engineers, and SpaceX itself.

In the belly of the beast

Zachary Dunn/Relativity Space

An engineer asked the jet pilots to fly the plane higher, where air pressure was lower. But the pilots only had enough fuel to circle the base once more before landing. According to Berger, that bought the SpaceX engineers about 10 minutes.

They sliced open the shrink wrap enveloping the rocket and found the C-17's onboard tool kit.

Dunn told engineer Mike Sheehan to hold his ankles and yank him out if the rocket started to explode. He wiggled into the Falcon 1's interstage - the section between the bulky base of the rocket, which propels it through the air, and the smaller section that continues into orbit.

In the darkness of the Falcon 1's belly, Dunn crawled toward the liquid-oxygen tank, sharp rocket parts scraping his back. He reached a large pressurization line to the fuel tank, twisted it open with a wrench, and heard the hiss of air flowing in. Then he called for Sheehan to help him out.

"Sheenhan took this as a cry for help, yanking Dunn out of the interstage across the tangle of pressurization lines and valves," Berger wrote. "It hurt like hell, but Dunn emerged to find his efforts paying off."

The SpaceXers went back to their seats, and the rocket reinflated before them as the jet descended to Hawaii.

The rocket launch that saved SpaceX

Though it survived the flight, the Falcon 1 was damaged from its brush with implosion. With just a week to spare, the SpaceX team rushed to dismantle it, replace broken parts, repair others, and reassemble their rocket.

SpaceX

Then on September 28, the Falcon 1 roared to life on Omelek Island, hauled itself off the ground, and soared into orbit.

In the control room, the team members "just exploded," Dunn told Berger. "We went absolutely wild. We were all jumping around. Hugging each other. Screaming. It was a righteous celebration."

SpaceX had proven that its rockets could get off the planet. Afterwards, the company scraped together enough contracts to keep funding flowing.

Dunn stayed at SpaceX for another decade, eventually becoming senior vice president of production and launch. Last year, he left SpaceX to oversee manufacturing at Relativity Space, a startup that aims to automate the rocket-production process with 3D printing.